The X-TWO impresses with

The X-TWO is a NEW ultimate light weight

paragliding and hang gliding rescue system

We didn´t just match a few existing systems together, no we developed a complete new rescue system. Not only the shape is new, we could optimize it even further. Immediately after deploying and opening of the canopy, the X-TWO sinks vertically and does NOT generate any FORWARD MOTION. The canopy is FULLY SYMMETRIC straight after the opening.

The packing method is super simple and can be done even by no experienced packers. Because of the SYMMETRICAL CONSTRUCTION of the X-TWO this rescue DOESN´T start to fly forward after the deployment. Thus, the X-TWO system is also suitable for absolute beginner pilots from the first day on. The X-TWO sinks extremely pendulum-stable due to its novel 3-CORNER CONSTRUCTION, the triangular shape has a self-stabilizing effect.

The X-TWO offers

We use only high-quality materials like LIROS (linen), UTT & DELCOTEX (cloth), GÜTH & WOLF (webbing), AMANN (thread), to achieve a unique product. All materials used are manufactured in EUROPE. Sophisticated and State of the art manufacturing methods guarantee best quality and a long service life according to ISO 9001.

TECHNICAL DETAILS

| max. | min. load | 90 | 45 kg |

| number of panels | 18 |

| weight of parachute incl. riser | 0,95 kg |

| area | 26 m² |

| number of lines | 12 |

| number of centerlines | 2 | 4 | 2 |

| sinkrate max load | EN 5,39 m|s |

| Test standard | LTF | EN (Air Turquoise) |

| certification | EP 216.2018 |

| container size | L 22cm | B 19cm | H 8,5cm |

| container volume | 3.100 cm³ (incl. lines) |

| system length | 4,5 m |

| max. area load | 3,46 kg|m² |

| max. | min. load | 110 | 50 kg |

| number of panels | 21 |

| weight of parachute incl. riser | 1,1 kg |

| area | 30,5 m² |

| number of lines | 15 |

| number of centerlines | 2 | 4 | 3 |

| sinkrate max load | EN 5,49 m|s |

| Test standard | LTF | EN (Air Turquoise) |

| certification | EP 215.2018 |

| container size | L 24cm | B 19,5cm | H 9,5cm |

| container volume | 4.000 cm³ (incl. lines) |

| system length | 4,8 m |

| max. area load | 3,6 kg|m² |

| max. | min. load | 130 | 70 kg |

| number of panels | 21 |

| weight of parachute incl. riser | 1,25 kg |

| area | 35,7 m² |

| number of lines | 15 |

| number of centerlines | 2 | 4 | 3 |

| sinkrate max load | EN 5,47 m|s |

| Test standard | LTF | EN (Air Turquoise) |

| certification | EP 204.2017 |

| container size | L 25cm | B 20cm | H 10cm |

| container volume | 4.600 cm³ (incl. lines) |

| system length | 4,9 m |

| max. area load | 3,64 kg|m ² |

| max. | min. load | 220 | 110 kg |

| number of panels | 30 |

| weight of parachute incl. riser | 2,25 kg |

| area | 63,9 m² |

| number of lines | 30 |

| number of centerlines | 3 | 5 | 3 |

| sinkrate max load | EN 5,35 |

| Test standard | LTF | EN (Air Turquoise) |

| certification | EP 206.2017 |

| container size | L 29cm | B 24cm | H 14cm |

| container volume | 7.000 cm³ (incl. lines) |

| system length | 7,3 m |

| max. area load | 3,44 kg|m ² |

MATERIALS for 90 | 110 | 130 | 220

Delcotex

UTT

Cousin Trestec

Liros

Güth & Wolf

Topp Textil

Amann

Wichard

EQUIPMENT

Newly developed 4-leaf container leaves nothing to be desired. Very compact design with separate line compartment for a quick and safe opening.

Line compartment

Separated line compartment for a problem-free stretching of the lines and an optimized opening of the canopy. First, the lines are released and with the last line loop the canopy is opened from the container only. This construction supports a maximum throwing power. The separated line compartment to the canopy also has another important reason. The coating of the dyneema lines is spared and a possible stick together with the fabric of the canopy is prevented.

Connecting loops rescue handle | container

At the container itself more connecting loops are sewn in order to ensure maximum compatibility with all on the market available harnesses. The main loop was designed as a triangle to allow an even better, easier and more powerful deployment.

New closure system of the cover sheet

The cover sheet is closed with a plastic stick or also known as Rigid Foil. The end of the cover sheet and the plastic stick itself is tucked into a flap of the container. With this construction we do not have anymore a disturbing line bundle on top of the deployment bag that could impair the opening of the rescue out of the harness container.

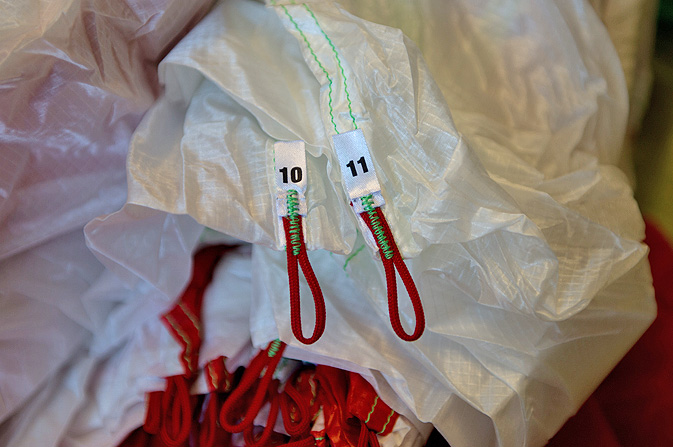

Numbering of the container leaves

The individual container sheets are numbered in order to be folded 1-5.

Replaceable rubber

The rubber for closing the container leaves is interchangeable.

Fully synthetic rubber bands

All X-dream Fly rescue devices are delivered with fully synthetic rubber bands from mid-2015 on. To get the maximum and proved X-dream Fly quality we decided to equip all our rescues with this rubber bands. The advantage of this rubber bands is a longer life and less sensitivity to humidity.

The packing tabs are numbered. It makes the packing process easier and prevents misstakes.

Make the packing much easier for you!

Packing Video X-TWO

More infos & download links for the X-TWO

You need help choosing your RESCUE?

The following report should help you in choosing your rescue system and show the problems of this complex issue!

If you have any questions do not hesitate to contact us

Team X-dream Fly… live your dream